ClassNK Reveals Overlooked Fuel Waste Risk in Heavy Weather

Image: ClassNK

Shipping companies focused on fuel efficiency and emissions reduction may be overlooking a hidden source of waste during rough seas that ClassNK researchers say can quietly erode performance, inflate fuel costs, and damage engine components.

In a new technical study, ClassNK’s research institute has revealed that a persistent mismatch between commanded and actual main engine speeds, commonly referred to as a “speed gap”, can cause vessels to burn significantly more fuel than necessary when navigating through rough seas. The phenomenon, though well known to engineers in principle, had not previously been quantified or clearly connected to real-world fuel losses and maintenance implications in this way.

“Even with speed reduction strategies in place, if the commanded engine speed remains higher than what the main engine can realistically achieve under current weather conditions, the governor will continue injecting excess fuel in an attempt to close the gap without success,” explains lead researcher Yuzhong Song.

The research has found that this could result in fuel wastage as high as 10–12% during periods of inclement weather, depending on the extent and duration of the mismatch.

The study analyzed onboard data from a Panamax bulk carrier as well as AIS and wave hindcast data across multiple trade routes. It found that vessels could waste up to 114 metric tons of fuel annually. This is equivalent to more than US $70,000 at current VLSFO prices in circumstances where engine speed orders are not adequately adjusted for rough conditions. On the Asia–US West Coast route alone, ships may experience such conditions for over 900 hours per year.

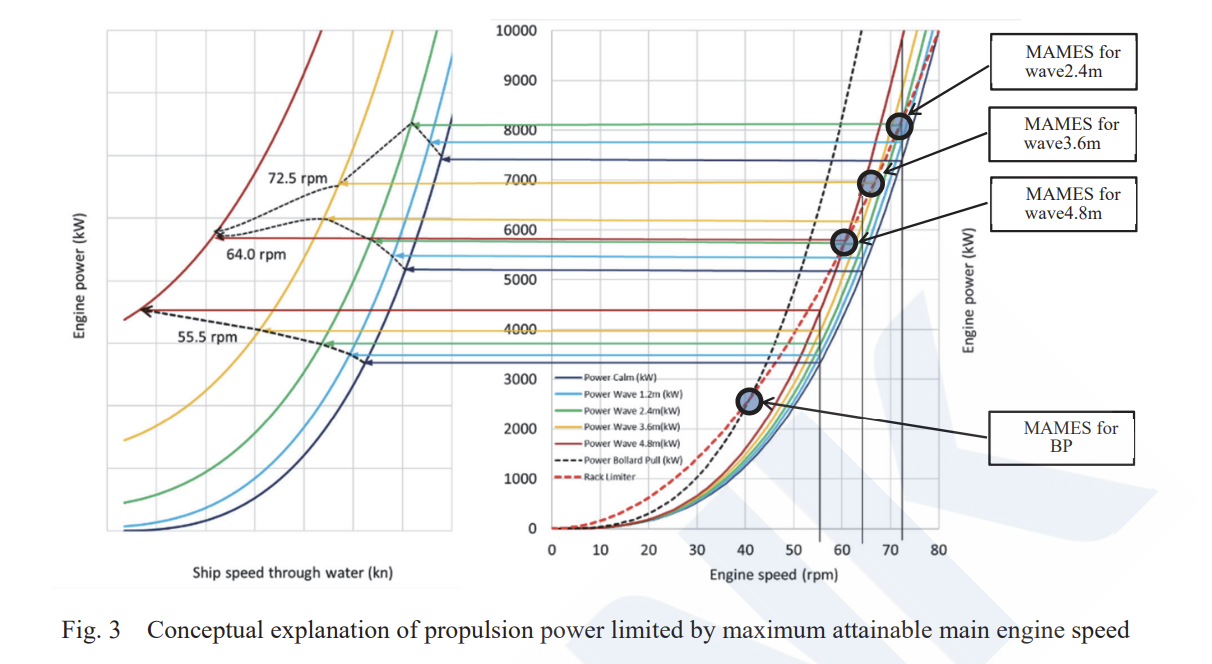

The root cause is mechanical. Main engines are subject to torque limits enforced by the fuel rack limiter, which restricts how much fuel can be injected per cycle to avoid overloading. This limit defines the Maximum Attainable Main Engine Speed (MAMES) under specific sea conditions. When crews set engine speed orders above this threshold, whether intentionally or due to outdated habits, the system responds with a futile injection of extra fuel.

Beyond the economic penalty, the ClassNK team highlights a serious operational risk. When an engine is stuck in a permanent acceleration state due to the speed gap, the turbocharger air-fuel ratio may drop, leading to incomplete combustion. This can cause soot fouling on turbine blades and nozzles, resulting in vibration, component wear, and eventual turbocharger failure.

Despite the severity of the findings, the proposed solution is strikingly simple. ClassNK suggests monitoring the engine speed gap in real-time and reducing the commanded speed until it disappears. Doing so eliminates both wasted fuel and excess mechanical strain. ClassNK encourages ship operators to review past voyage data to identify where gaps have occurred, and to build these insights into crew training and voyage planning.

With carbon-neutral fuels set to remain significantly more expensive than conventional HFO, eliminating all causes of waste will be crucial to decarbonisation goals and commercial success.